Cantilever Beam: Calculix vs Code Aster

Written on April 29th, 2022 by Joseph

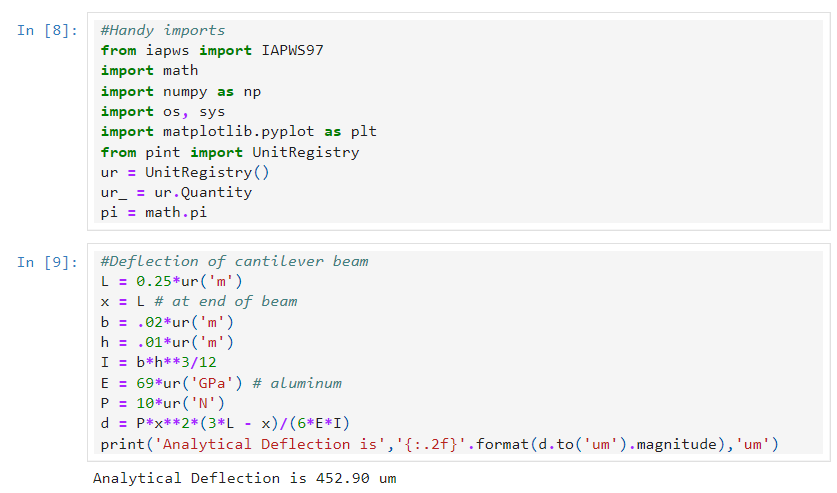

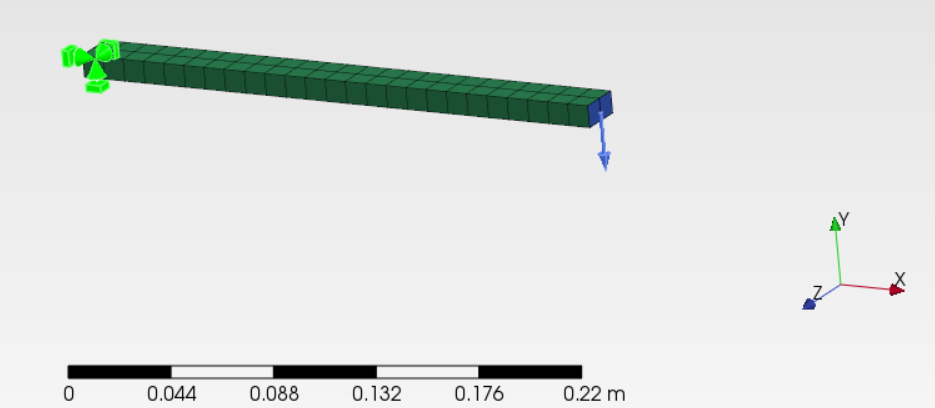

I am interested in making a number of comparisons to validate different finite element and finite volume approaches/softwares. This post will compare the results from two open source FEA packages called Calculix and Code Aster. The first step is to calculate the deflection using an analytical approach for comparison to the numerical approaches. For this comparison, I will look at a cantilevered beam. The beam is fixed at one end and all of the loading is applied as a point load at the other.

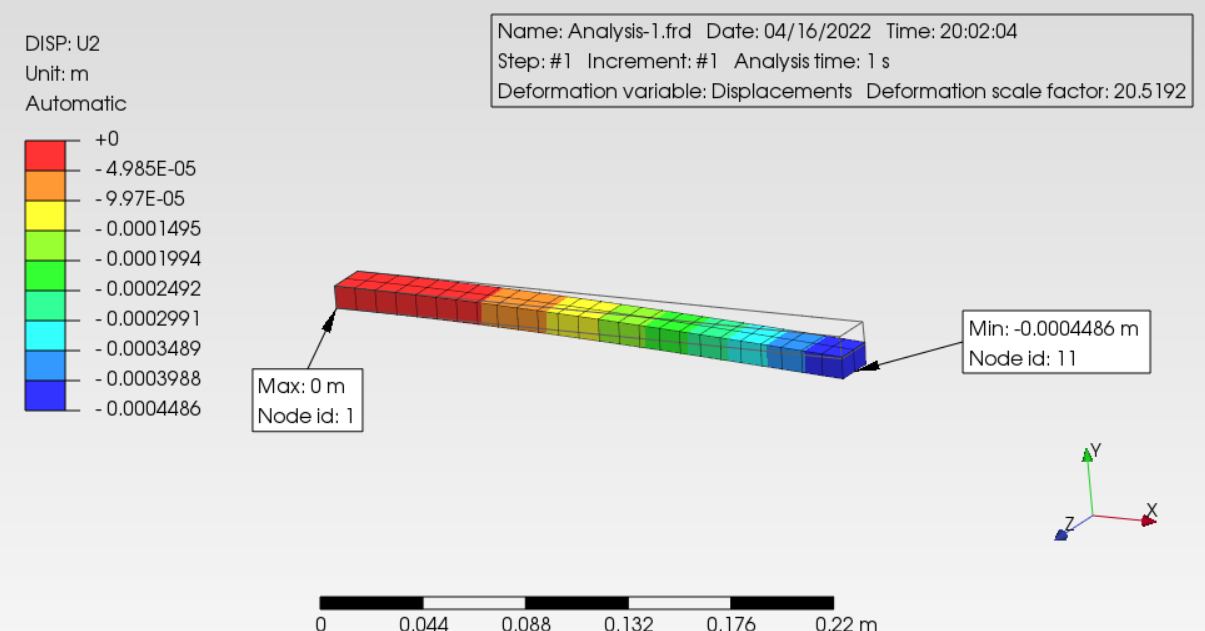

I will first solve this with Calculix using PrePoMax as a convenient interface to set up the problem. The mesh was generated with one layer of second order hex elements using Salome. More layers would be needed for the solution to be independent of the mesh, but this is fine for comparing the results of the two softwares to each other.

Here is the abbreviated step file used as input for CCX.

**

** Heading +++++++++++++++++++++++++++++++++++++++++++++++++

*Heading

Hash: OzciZ7SO, Date: 04/23/2022, Unit system: M_KG_S_C

** Nodes +++++++++++++++++++++++++++++++++++++++++++++++++++

*Node

... hidden data ...

** Elements ++++++++++++++++++++++++++++++++++++++++++++++++

*Element, Type=C3D20, Elset=Solid_part-1

... hidden data ...

** Node sets +++++++++++++++++++++++++++++++++++++++++++++++

*Nset, Nset=Internal-1_fix

... hidden data ...

*Nset, Nset=Internal-1_load

... hidden data ...

*Nset, Nset=Internal_Selection-1_Fixed-1

... hidden data ...

*Nset, Nset=Internal-1_Internal_Selection-1_Surface_traction-1

... hidden data ...

** Element sets ++++++++++++++++++++++++++++++++++++++++++++

*Elset, Elset=alum

... hidden data ...

*Elset, Elset=Internal-1_fix_S1

... hidden data ...

*Elset, Elset=Internal-1_load_S2

... hidden data ...

*Elset, Elset=Internal-1_Internal_Selection-1_Surface_traction-1_S2

... hidden data ...

** Surfaces ++++++++++++++++++++++++++++++++++++++++++++++++

*Surface, Name=fix, Type=Element

Internal-1_fix_S1, S1

*Surface, Name=load, Type=Element

Internal-1_load_S2, S2

*Surface, Name=Internal_Selection-1_Surface_traction-1, Type=Element

Internal-1_Internal_Selection-1_Surface_traction-1_S2, S2

** Materials +++++++++++++++++++++++++++++++++++++++++++++++

*Material, Name=aluminum

*Elastic

69000000000, 0.3

*Solid section, Elset=alum, Material=aluminum

** Step-1 ++++++++++++++++++++++++++++++++++++++++++++++++++

*Step

*Static

** Boundary conditions +++++++++++++++++++++++++++++++++++++

*Boundary, op=New

** Name: Fixed-1

*Boundary

Internal_Selection-1_Fixed-1, 1, 6, 0

** Loads +++++++++++++++++++++++++++++++++++++++++++++++++++

*Cload, op=New

*Dload, op=New

** Name: Surface_traction-1

*Cload

5, 2, 4.16666667E-001

7, 2, 4.16666667E-001

12, 2, 8.33333333E-001

11, 2, 8.33333333E-001

165, 2, -1.66666667E+000

167, 2, -1.66666667E+000

270, 2, -3.33333333E+000

164, 2, -1.66666667E+000

8, 2, 4.16666667E-001

6, 2, 4.16666667E-001

166, 2, -1.66666667E+000

168, 2, -1.66666667E+000

163, 2, -1.66666667E+000

*Node file

RF, U

*El file

S, E

** End step ++++++++++++++++++++++++++++++++++++++++++++++++

*End step

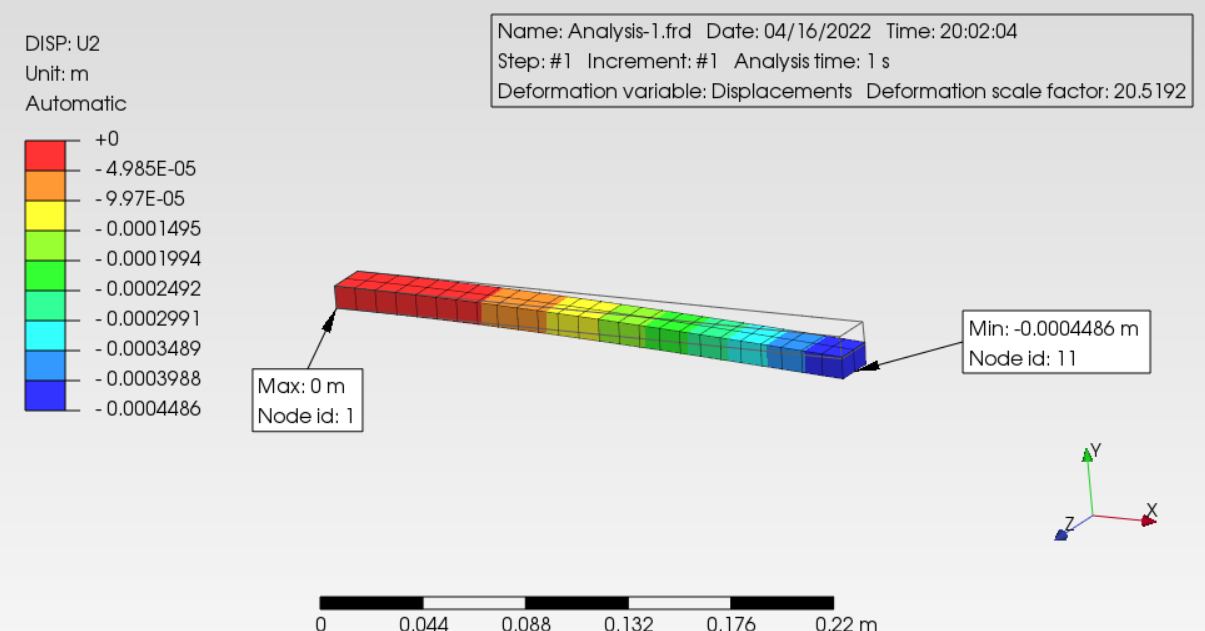

Results of the deflection are shown here.

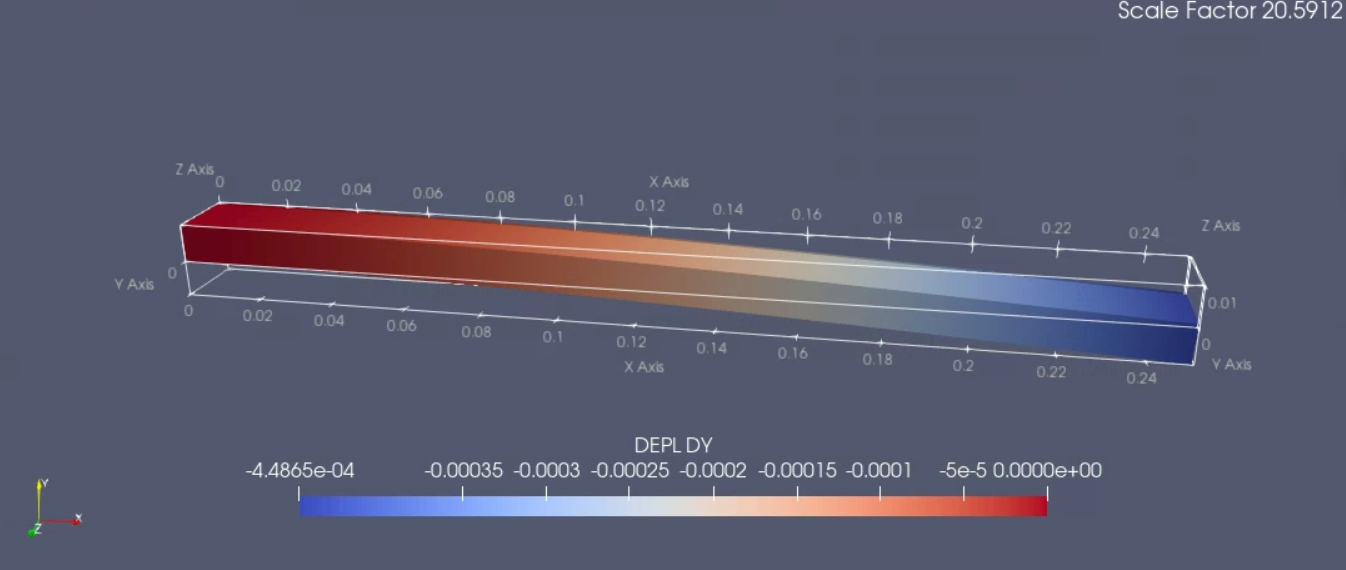

The next approach was to use Code Aster to solve the same problem. Here is the comm file from Code Aster.

DEBUT(LANG='FR')

mesh = LIRE_MAILLAGE(UNITE=20)

model = AFFE_MODELE(AFFE=_F(MODELISATION=('3D', ),

PHENOMENE='MECANIQUE',

TOUT='OUI'),

MAILLAGE=mesh)

mater = DEFI_MATERIAU(ELAS=_F(E=69000000000.0,

NU=0.3))

fieldmat = AFFE_MATERIAU(AFFE=_F(MATER=(mater, ),

TOUT='OUI'),

MODELE=model)

fix = AFFE_CHAR_MECA(DDL_IMPO=_F(DX=0.0,

DY=0.0,

DZ=0.0,

GROUP_MA=('fix', )),

MODELE=model)

load1 = AFFE_CHAR_MECA(FORCE_FACE=_F(FY=-50000.0,

GROUP_MA=('load', )),

MODELE=model)

reslin = MECA_STATIQUE(CHAM_MATER=fieldmat,

EXCIT=(_F(CHARGE=load1),

_F(CHARGE=fix)),

MODELE=model)

IMPR_RESU(FORMAT='MED',

RESU=_F(MAILLAGE=mesh,

RESULTAT=reslin),

UNITE=2)

FIN()

Analytical Deflection 452.90 um

Calculix Deflection is 448.6 um

Code Aster Deflection is 448.7 um

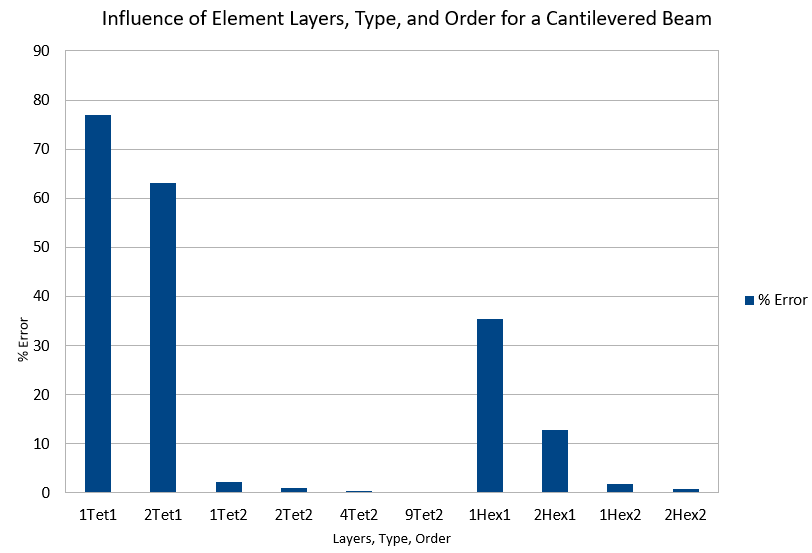

Both solvers have excellent agreement with each other and are within 1% of the analytical solution. This is good considering the mesh is only one layer thick. In another post I will explore how the solution changes with different element types and number layers.